Quotation and price cost function

Presentation

TOLfab version 4.8 includes a new function which permits to do manufacturing quotations or to

know the cost price of a part, a sheet or a set of sheets in a very easy way.

TOLfab, software for manufacturing, contains a "material" database where are stored all the cutting

parameters as speed or pressure of the used gas in relation with each material code / thickness.

Times calculation

Calculation of cutting times given by the software is now the nearest possible of the reality.

It includes as well the various kinds of contours (small/middle/big) as the common cut, the piercing

kinds, but too times of rising up and down of the heads, speeding up and speeding down times and many

other parameters not visible for the user.

As the database gives a right time calculation, the quotation function allows to get linear lengths

for each kind of cutting and too the final results, keeping in account the horary cost of the machine,

the cost of the material and even the gas consummations.

Use

Use this function is very easy because it is just necessary to create the part in the software to get

a quotation that may be printed and which is available in a database as Access.

The quotation function gives the whole calculated results in 2 clicks of mouse.

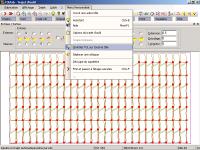

Example (See)

- Material code: E24-O2

- Thickness: 8.000 mm

- Machine cost: 110.00

- Gaz N2 cost: 1.200

- Gaz O2 cost: 1.200

- Material cost: 180.00

- Scrap rate: 54.00 %

- Parts weight: 783.21 kg

- Cutting speed small contour: 100.00 mm/mn

- Cutting speed middle contour: 900.00 mm/mn

- Cutting speed big contour: 2200.0 mm/mn

- Length small contour: 14756.4 mm

- Length middle contour: 21462.0 mm

- Length big contour: 116195 mm

- Length in full speed: 131717 mm

- Fast piercing number: 902

- Cutting time small contour: 147'33"

- Cutting time middle contour: 23'50"

- Cutting time big contour: 52'48"

- Time at full speed moving: 6'37"

- Fast piercing time: 7'31"

- Cutting gas consummation: 3.283 m3 d'oxygène

- Total machining time: 238'21"

- Cost price: 582.43

The whole calculation data being easily accessible, it is too interesting to have the possibility

of modify them to do tests of cost price.

For a more difficult set as a nesting or a group of nestings, these data are automatically stored for

each manufacturing. When a sheet is nested and the toolpath done, less than 10 secondes are necessary

to get a global quotation.

This function is available without extra charge (except an additional post in network) in all the models

including the driving of a machine. It is by another way commercialized under the model name "Quotation"

of TOLfab.

Appendix

Variables about the machine are in "Maintenance" "Options..." "Advanced..." :

- Full moving speed

- Marking speed

- Speeding up time

- Speeding down time

- Time of head rising up and down from the original position

- Time of head rising up and down from a semi-high position

- Time of head rising up and down from a low position

- Horary cost of the machine

- Oxygen cost (/m3)

- Nitrogen cost (/m3)

- Other gas cost

- Increase factor

All the following variables are managed by material code / thickness in the material (depend on the machine)

Variables about cutting lengths and piercing kinds:

- Small contour size

- Middle contour size

- Big contour size

- Micro-piercing size or pulsed piercing

Variables about cutting times (Linear*Speed):

- Small contour speed

- Middle contour speed

- Big contour speed

- Default cutting speed

- Open contour and common cut speed

Variables about piercing lenthg times (Number of piercing*time):

- Piercing time

- Auxiliary piercing time

Variables about gas consummation (taking in account the kind of the nozzle, of the kind of gas, the pressure, the king of cutting and its length):

- Gas pressure

- Cutting gas kind

- Marking gas kind

- Piercing gas kind

- Auxiliary piercing gas kind

Variables about material cost (weight*price for a tun) :

- Material cost (/tun)

- Weight calculated in relation with the used area or the total area

|

|

|

|

|