Plasma / Oxycutting

An easy, complete, suitable solution

- Programming center including creation, nesting, piloting and PC/NC connection

- The full automatic running can be modified manually

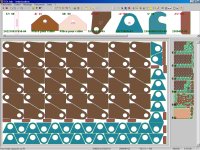

- Data base of parts, materials and nestings

- Automatic nesting

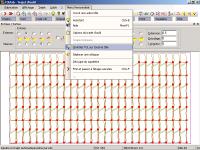

- Automatic toolpath

- Integrated common cut function

- Off-line running allows to do nestings while the machine cuts

Make savings

- Easy and automatic system

- Bridges between parts to save pierce time and then electrodes or time

- Cut more in the same time with common cut beetween the parts (-20 % cutting time and scrap rate < 10 %)

- Possibility to unit common cut functions with multi-torch process to cut more parts faster

- Get a quotation by printing in 2 clicks of mouse the real cost of a part (calculated and not only estimated)

- Conversion of bitmap files in DXF files

A set of technical answers

- Cutting quality is controlled thanks to a whole management of cutting speeds regarding to the thickness of the sheet and to the size of the contour elements

- Automatic loops for process of sharp angles (oxycutting)

- Suppression of collision problems due to cutting (patented process of management of the height sensor)

- Significant reduction of relief, particularly in the case of little circles

- Common cut answers fit to plasma cutting technology (by a suitable management of the height sensor) and oxycutting (par a suitable management of speed steps

- A system allowing cutting in hidden time thanks to the management of the NC functions while the operator is not there

|

|

|

|

|